CNC in refrigeration technology: precision and efficiency for modern cooling systems

CNC technology in the production of cooling systems

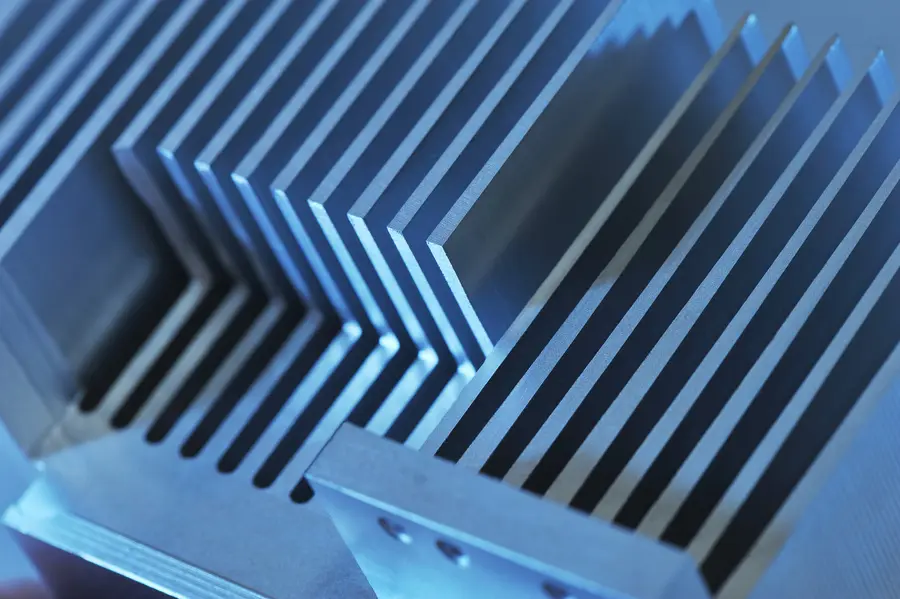

CNC precision machining for cooling technology

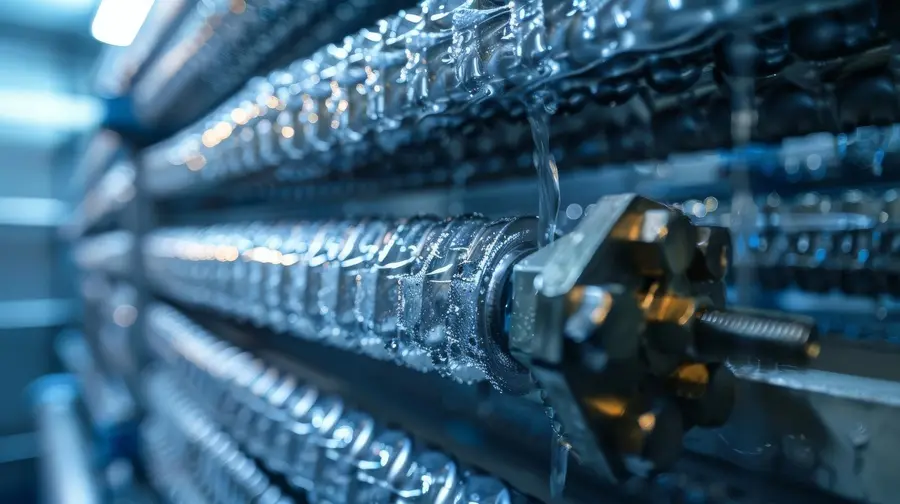

Automated cooling component production

CNC milling in refrigeration technology

CNC turning of cooling elements

CNC models in refrigeration technology

CNC prototyping in refrigeration technology:

Fast and precise

Our experts will be happy to advise you in detail on your ideal solution with the best CNC machine for your refrigeration technology requirements. In our wide range you will find machines from a wide variety of manufacturers, ideally tailored to your needs. Feel free to contact us at any time and let our experienced team advise you. We will be happy to provide you with individual advice. Get in touch with us today!

Get in touch with us: :+49 (0) 611 5101990